There is no absolute advantage or disadvantage between hot-dip galvanizing and electrogalvanizing. The key lies in scene adaptation: Choose hot-dip galvanizing: heavy anti-corrosion, long life, high load scene. Choose electrogalvanizing: low cost, high precision, short-term application.

23

2025

/

05

15

2025

/

05

Steel bars: the core framework and performance analysis of modern buildings

Steel bars: the core framework and performance analysis of modern buildings

15

2025

/

05

Cold Rolled vs. Hot Rolled Coils: Key Differences Explained

Cold-rolled coil and hot-rolled coil each have their own unique characteristics and application areas in the steel industry.

09

2025

/

05

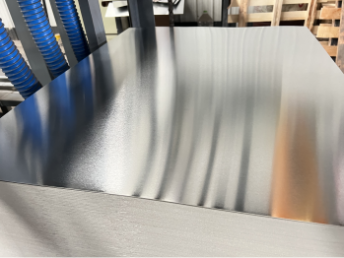

Effect of zinc layer thickness on corrosion resistance of galvanized steel sheet

Galvanized steel sheet is an important anti-corrosion steel material and is widely used in construction, automobiles, home appliances and other fields. The core guarantee of its anti-corrosion performance comes from the surface zinc layer protection, and the thickness of the zinc layer is one of the key factors determining the corrosion resistance of galvanized steel sheet. This paper deeply explores the relationship between zinc layer thickness and corrosion resistance of galvanized steel sheet, and provides a theoretical basis for material selection in engineering applications. Zinc layer protection mechanism The anti-corrosion protection of galvanized steel sheet mainly relies on the dual protection of the zinc layer: 1. Physical barrier effect: The zinc layer, as a dense metal covering layer, effectively blocks the direct contact between the steel plate and the corrosive medium. The standard electrode potential of zinc (-0.76V) is lower than that of iron (-0.44V). When the coating is damaged, zinc will corrode first, thereby protecting the base steel. 2. Electro chemical protection: When zinc and iron form a primary battery, zinc sacrifices itself as an anode to protect the iron matrix. This cathodic protection effect is still effective even when the zinc layer is scratched or damaged. Factors affecting the thickness of the zinc layer The thickness of the zinc layer of galvanized steel sheets is mainly affected by the following factors: - Production process (hot-dip galvanizing, electro-galvanizing, etc.) - Galvanizing time - Zinc liquid composition - Steel sheet surface state - Cooling rate In the hot-dip galvanizing process, the zinc layer thickness is usually controlled within the range of 10-50μm, while the zinc layer thickness of electro-galvanized is generally thinner, usually between 3-20μm. Relationship between zinc layer thickness and corrosion resistance 1. Thickness and corrosion rate Studies have shown that the thickness of the zinc layer is positively correlated with the corrosion resistance of galvanized steel sheets. Thicker zinc layers can provide more lasting protection because: - Increases the time required for the corrosive medium to penetrate the zinc layer - Provides more sacrificial anode materials - Reduces the probability of local corrosion Experimental data show that in the same corrosion environment, the service life can be extended by 2-3 times if the zinc layer thickness is doubled. 2. Critical thickness phenomenon The study found that there is a critical zinc layer thickness (about 20μm). When the zinc layer thickness is lower than this value, the corrosion rate will be significantly accelerated. This is because: - Thin zinc layers are more likely to form penetrating corrosion channels - The duration of cathodic protection is shortened - The impact of surface defects is more significant 3. Performance differences in different environments The protective effect of zinc layer thickness varies in different corrosive environments: Industrial atmospheric environment: It is recommended to use a thicker zinc layer (≥20μm) Marine environment: A thicker zinc layer (≥30μm) is required and alloying treatment is considered Dry indoor environment: A thinner zinc layer (10-15μm) can meet the requirements Acid and alkali environment: Special treatment is required, and simply increasing the zinc layer thickness has limited effect Recommendations for the selection of zinc layer thickness In actual engineering applications, the selection of zinc layer thickness should take into account the following factors: 1. Use environment: Determine the basic thickness requirements according to the environmental corrosion level 2. Expected service life: The zinc layer thickness needs to be increased for long-term use 3. Cost factors: Balance anti-corrosion performance and economy 4. Processing requirements: Subsequent processing may affect the integrity of the zinc layer 5. Appearance requirements: Different thicknesses may affect the surface quality Generally recommended: - Ordinary construction use: 40-80g/m² (about 6-12μm) - Harsh industrial environment: 100-150g/m² (about 14-21μm) - Marine engineering application: 180-275g/m² (about 25-40μm) Conclusion Zinc layer thickness is one of the decisive factors affecting the corrosion resistance of galvanized steel sheets. Reasonable selection of zinc layer thickness can significantly extend the service life of the material, but it is necessary to comprehensively consider factors such as the use environment and cost-effectiveness. With technological advances, by optimizing the structure and composition of the zinc layer, it is expected to obtain better anti-corrosion effects at the same thickness, which will be an important direction for future research.

30

2025

/

04

Hot-dip galvanizing vs. Electro galvanizing: Which galvanized wire is better for your needs?

Galvanized wire is widely used in construction, agriculture, power and other industries due to its rust-proof and corrosion-resistant properties. However, different galvanizing processes will directly affect the performance and application scenarios of the product. The current mainstream galvanizing processes are divided into hot-dip galvanizing and electro-galvanizing , which have obvious differences in process, corrosion resistance, cost, etc. This article will compare these two galvanized wires in detail to help you make the best choice based on your actual needs. 1. Process and coating characteristics (1) Hot-dip galvanizing (HDG) Hot-dip galvanizing is to immerse the steel wire in high-temperature molten zinc liquid (about 450°C) to form a metallurgical bonding layer between zinc and the iron matrix. Since the zinc liquid completely wraps the steel wire, the coating is relatively thick, usually between 20-100 microns, and the surface may show zinc flower crystal lines and be slightly rough. Advantages: Super corrosion resistance: The zinc layer is thick and suitable for long-term outdoor use, such as marine environment and chemical facilities. Strong adhesion: Zinc and iron form an alloy layer that is not easy to peel off. Long life: It can be used for decades in harsh environments. Disadvantages: Rough surface: Not suitable for scenes with high precision or high aesthetics requirements. High cost: High zinc consumption and complex process. (2) Electro galvanizing Electro galvanizing uses an electrolytic process to evenly deposit a layer of zinc on the surface of the steel wire. The coating is relatively thin, usually between 3-20 microns. Because it is electro chemical deposition, the coating is more uniform and smooth, suitable for fine processing. Advantages: Smooth and delicate surface: Suitable for fields such as electronics and home appliances that require high aesthetics. Low cost: Low zinc content, suitable for mass production. Good processing performance: Suitable for precision manufacturing, such as springs and small hardware. Disadvantages: Weak corrosion resistance: The zinc layer is thin and is prone to rust when exposed to a humid environment for a long time. General adhesion: The bonding between the zinc layer and the substrate is not as strong as hot-dip galvanizing. 2. Comparison of applicable scenarios Typical applications of hot-dip galvanized wire Construction industry: Rebar binding, scaffolding fixing, steel structure reinforcement. Transportation facilities: Highway guardrails, railway protection nets, bridge cables. Marine engineering: Port fences, ship accessories, seawater aquaculture cages. Agriculture: Greenhouse brackets, livestock fences, bird-proof nets. Typical applications of electro galvanized wire Electronic appliances: Circuit shielding wires, precision springs, electronic components. Household hardware: clotheslines, hooks, metal braids. Packaging industry: strapping tape, light strapping wire. Auto parts: wiring harness fixing, small fasteners. 3. How to choose the right galvanized wire? When to choose hot-dip galvanized wire Long-term rust prevention is required, such as outdoor construction and marine environment. High mechanical strength requirements, such as heavy structural reinforcement. Adequate budget, pursuit of longer service life. When to choose electro galvanized wire Short-term rust prevention needs, such as indoor hardware and packaging materials. Smooth surface is required, such as precision instruments and electronic products. Cost-sensitive, hoping to reduce procurement costs. 4. Conclusion Hot-dip galvanized wire and electro-galvanized wire each have their own advantages. When choosing, you need to consider the use environment, budget, aesthetics, corrosion resistance requirements and other factors: Hot-dip galvanized wire is more suitable for applications that are exposed to harsh environments for a long time, such as construction, transportation, and marine engineering. Electro-galvanized wire is more suitable for short-term protection or high-precision processing, such as electronics, home appliances, and light bundling. Correctly selecting the galvanizing process can not only improve product performance, but also optimize costs. I hope this article can help you make a more informed decision!

30

2025

/

04