PRODUCT CENTER

OUR ADVANTAGE

AAA Level

Credit Steel Supplier

10+

Stock Warehouses

Support

Three-party Inspection

Large Order

Preferential Policies

Order Now

+8613739652120

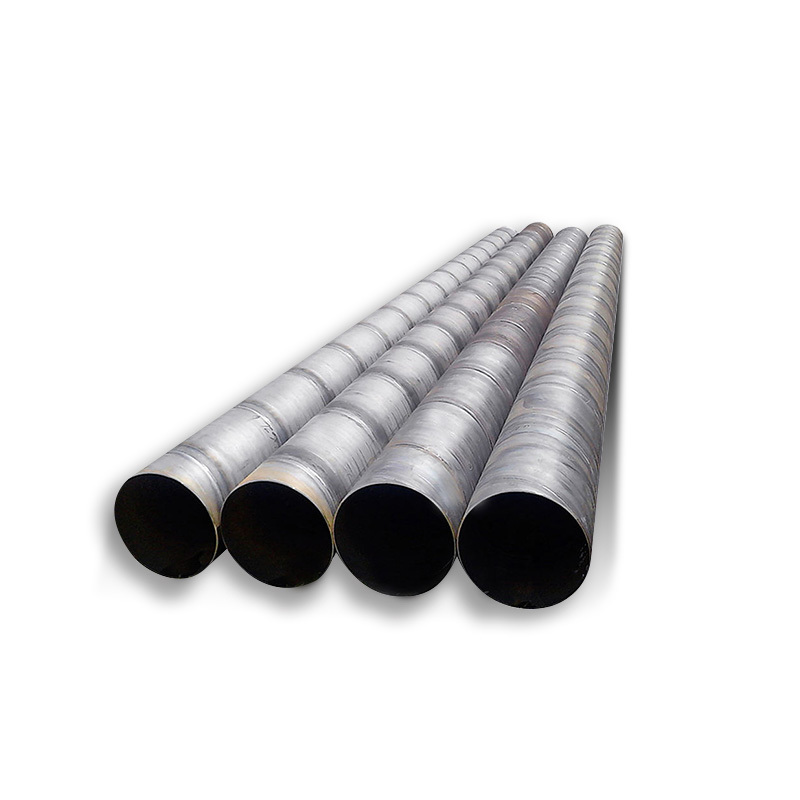

Spiral Submerged Arc Welded Pipe SSAW

The spiral submerged arc welded pipe is made of hot-rolled steel strip as raw material, and is usually made by constant temperature spiral forming and automatic submerged arc welding. The manufacturing process is to roll the steel strip, make the rolling direction at a certain angle to the center direction of the tube, and then form and weld, so the weld is spiral. Can provide API SPEC 5L steel pipe, GB / T3091,GB / T9711-2011,EN10219,ASTM A252 standard steel pipe.

The longitudinal submerged arc welded pipe is made of steel plate as raw material, which is formed by a forming machine, and then double-sided submerged arc welding is carried out. Through this process, the LSAW pipe will have excellent ductility, toughness, uniformity, plasticity and good sealing performance. The production equipment can be produced quickly, easy to replace, and the product specification range of LSAW pipe is large. The production line can produce welded pipe diameter 406-4500mm, wall thickness 8mm-100mm.

Resistance welded pipe ERW is formed by hot rolled coil through forming machine. The skin effect and proximity effect of the high frequency current are used to heat and melt the edges of the tube blank. Pressure welding is carried out under the action of squeeze rollers. Realize production. The production process of welded steel pipes is simple, the production efficiency is high, the varieties and specifications are many, and the equipment is few, but the general strength is lower than that of seamless steel pipes.

Galvanized pipe Galvanized steel pipe, also known as galvanized pipe, is divided into two kinds of hot dip galvanized and electro galvanized. The hot-dip galvanized layer is thick, the coating is uniform, the adhesion is strong, and the service life is long. Zinc is commonly used to galvanize or coat these metal tubes. The galvanizing process for steel pipes involves immersing the metal pipe in a bath containing 450 degrees Fahrenheit molten zinc. After a few minutes, the hot-dip galvanizing process is complete.

304 stainless steel is a kind of universal stainless steel material, rust resistance than 200 series of stainless steel material is stronger. High temperature resistance is also better, can be as high as 1000-1200 degrees. 304 stainless steel has excellent corrosion resistance and good intergranular corrosion resistance. For oxidizing acids, it is concluded in the experiment that 304 stainless steel has strong corrosion resistance in nitric acid with a concentration of less than or equal to 65% of the boiling temperature. It also has good corrosion resistance to alkali solution and most organic and inorganic acids.

304L is one of the austenitic stainless steels with a chromium content of at least 18%, a nickel content of at least 8%, and a maximum carbon content of 0.03. 304L stainless steel is an ideal choice for various household and commercial applications, with excellent corrosion resistance, ease of manufacturing and excellent formability. Austenitic stainless steels are also considered to be the easiest to weld among high alloy steels and can be welded by all fusion and resistance welding processes.

Grade 316 stainless steel is an austenitic form of stainless steel with a molybdenum content of 2-3%. The addition of molybdenum makes the metal more resistant to pitting and corrosion and improves its resistance to exposure to high temperatures. This grade of stainless steel is particularly effective when used in acidic environments. With this metal, corrosion caused by acetic acid, hydrochloric acid and other forms of acid can be prevented.

316L stainless steel is an austenitic stainless steel metal alloy that contains nickel and molybdenum, making it corrosion resistant. 316L is a 316 low carbon grade. This grade is not affected by sensitization (grain boundary carbide precipitation). It is often used for large-gauge welded parts (approximately over 6mm). 316L stainless steel has higher creep, fracture stress and tensile strength than chromium nickel austenitic stainless steel at high temperature.