BS4449 Steel Reinforcement Rebar

Classification :

PRODUCT DETAILS

BS4449 Steel Reinforcement Rebar Description

BS4449 is yet another deformed steel bar standard. It is also differentiated as per European standards. When it comes to manufacturing, the steel bars falling in this standard are also hot rolled, which means that they are also used for general purposes, i.e. in common construction projects. These deformed bars are also available between 12 mm to 30 mm diameter size. And the common lengths that they are available in are 9 m and 12 m. Though, it might vary highly.

| BS 4449:97 British Rebar Specifications | |||||||||||||||

| Rated Diameter |

Nominal Cross Section Area | Weight | EN To The Ribs (mm) | Longitudinal Ribs (mm) | Pitch / Step mm |

Ribs Tip Distance mm |

|||||||||

| Kg / m |

Tolerance % |

Height | Width | Height | Width | ||||||||||

| mm | m㎡ | min. | max. | min. | max. | min. | max. | min. | max. | min. | max. | min. | max. | ||

| 6 | 28.3 | 0.222 | ± 9 | 0.3 | 0.6 | 0.48 | 0.72 | 0.3 | 0.84 | 0.48 | 1.2 | 3,.0 | 4.8 | 1.5 | 2.3 |

| 8 | 50.3 | 0.395 | ± 6.5 | 0.4 | 0.8 | 0.64 | 0.96 | 0.4 | 0.84 | 0.64 | 1.6 | 4.0 | 6.4 | 2.0 | 3.1 |

| 10 | 78.5 | 0.616 | 0.5 | 1.0 | 0.8 | 1.2 | 0.5 | 0.84 | 0.8 | 2.0 | 5.0 | 8.0 | 2.5 | 3.9 | |

| 12 | 113.1 | 0.888 | ± 4.5 | 0.6 | 1.2 | 0.96 | 1.44 | 0.6 | 0.84 | 0.96 | 2.4 | 6.0 | 9.6 | 3.0 | 4.7 |

| 16 | 201.1 | 1.579 | 0.8 | 1.6 | 1.28 | 1.92 | 0.8 | 0.84 | 1.28 | 3.2 | 8.0 | 12.8 | 4.0 | 6.2 | |

| 20 | 314.2 | 2.466 | 1.0 | 2.0 | 1.6 | 2.4 | 1.0 | 0.84 | 1.6 | 4.0 | 10.0 | 16.0 | 5.0 | 7.8 | |

| 25 | 490.9 | 3.854 | 1.25 | 2.5 | 2.0 | 3.0 | 1.25 | 0.84 | 2.0 | 5.0 | 12.5 | 20.0 | 6.2 | 9.8 | |

| 32 | 804.2 | 6.313 | 1.60 | 3.2 | 2.56 | 3.84 | 1.60 | 0.84 | 2.56 | 6.4 | 16.0 | 25.6 | 8.0 | 12.5 | |

| 40 | 1256.6 | 9.864 | 2.0 | 4.0 | 3.2 | 4.8 | 2.0 | 0.84 | 3.2 | 8.0 | 20.0 | 32.0 | 10.0 | 15.7 | |

| 50 | 1963.5 | 15.413 | 2.5 | 5.0 | 4.0 | 6.0 | 2.5 | 0.84 | 4.0 | 10.0 | 25.0 | 40.0 | 12.5 | 19.6 | |

| BS 4449:97 Steel Rebar Mechanical Properties | ||||

| Quality |

Akma N / mm2< | Akma / Pull Rate N/mm2 | Elongation Elasticity | Total max. % AGT |

| min. | min. | min. | min. | |

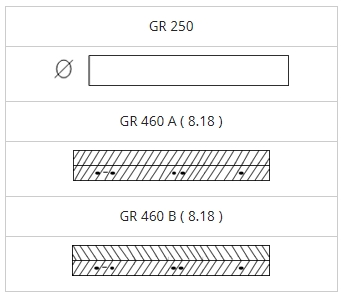

| GR 250 | 250 | Akma x 1.15 | 22 | – |

| GR 460 A | 460 | Akma x 1.05 | 12 | 2.5 |

| GR 460 B | 460 | Akma x 1.08 | 14 | 5 |

| BS 4449:97 Steel Rebar Chemical Properties | |||||

| Element | GR 250 % max. | GR 460 A / B % max. | Ribs and Marking Method | ||

| Casting | Product | Casting | Product |  |

|

| C | 0.25 | 0.27 | 0.25 | 0.27 | |

| P | 0.060 | 0.065 | 0.050 | 0.055 | |

| S | 0.060 | 0.065 | 0.050 | 0.055 | |

| N | 0.012 | 0.013 | 0.012 | 0.013 | |

| CE | 0.42 | 0.45 | 0.51 | 0.54 | |

| Mn Cr+Mo+V Ni+Cu | |||||

| CE = C + ————- + ——————- + —————– | |||||

| 6 5 15 | |||||

Scope of Application

Widely used in houses, bridges, roads, especially railways and other civil engineering.

| USA | Japan | Germany | U.K. |

|

France | Italy | Spain | Switzerland | China | |

|

AISI/SAE |

JIS |

W‐nr. |

DIN |

BS |

EN |

AFNOR |

UNI |

UNE |

SS |

GB |

|

A570.36 |

STKM 12A |

1.0038 |

RSt.37‐2 |

4360 |

‐ |

E 24‐2 |

‐ |

‐ |

1311 |

15 |

|

- |

STKM 12C |

- |

- |

40 C |

- |

Ne |

- |

- |

- |

- |

|

1015 |

‐ |

1.0401 |

C15 |

080M15 |

‐ |

CC12 |

C15, C16 |

F.111 |

1350 |

15 |

|

1020 |

‐ |

1.0402 |

C22 |

050A20 |

2C |

CC20 |

C20, C21 |

F.112 |

1450 |

20 |

|

1213 |

SUM22 |

1.0715 |

9SMn28 |

230M07 |

1A |

S250 |

CF9SMn28 |

F.2111 |

1912 |

Y15 |

|

11SMn28 |

||||||||||

|

12L13 |

SUM22L |

1.0718 |

9SMnPb28 |

‐ |

‐ |

S250Pb |

CF9SMnPb28 |

11SMnPb28 |

1914 |

‐ |

|

‐ |

‐ |

1.0722 |

10SPb20 |

‐ |

‐ |

10PbF2 |

CF10Pb20 |

10SPb20 |

‐ |

‐ |

|

1215 |

‐ |

1.0736 |

9SMn36 |

240M07 |

1B |

S300 |

CF9SMn36 |

12SMn35 |

‐ |

Y13 |

|

12L14 |

‐ |

1.0737 |

9SMnPb36 |

‐ |

‐ |

S300PB |

CF9SMnPb36 |

12SMnP35 |

1926 |

‐ |

|

1015 |

S15C |

1.1141 |

Ck15 |

080M15 |

32C |

XC12 |

C16 |

C15K |

1370 |

15 |

|

1025 |

S25C |

1.1158 |

Ck25 |

‐ |

‐ |

‐ |

‐ |

‐ |

‐ |

25 |

|

A572-60 |

‐ |

1.890 |

StE380 |

4360 55 |

‐ |

‐ |

FeE390KG |

‐ |

2145 |

‐ |

|

1035 |

‐ |

1.0501 |

C35 |

060A35 |

‐ |

CC35 |

C35 |

F.113 |

1550 |

35 |

|

1045 |

‐ |

1.0503 |

C45 |

080M46 |

‐ |

CC45 |

C45 |

F.114 |

1650 |

45 |

|

1140 |

‐ |

1.0726 |

35S20 |

212M36 |

8M |

35MF4 |

‐ |

F210G |

1957 |

‐ |

|

1039 |

‐ |

1.1157 |

40Mn4 |

150M36 |

15 |

35M5 |

‐ |

‐ |

‐ |

40Mn |

|

1335 |

SMn438(H) |

1.1167 |

36Mn5 |

‐ |

‐ |

40M5 |

‐ |

36Mn5 |

2120 |

35Mn2 |

|

1330 |

SCMn1 |

1.1170 |

28Mn6 |

150M28 |

14A |

20M5 |

C28Mn |

‐ |

‐ |

30Mn |

|

1035 |

S35C |

1.1183 |

Cf35 |

060A35 |

‐ |

XC38TS |

C36 |

‐ |

1572 |

35Mn |

|

1045 |

S45C |

1.1191 |

Ck45 |

080M46 |

‐ |

XC42 |

C45 |

C45K |

1672 |

Ck45 |

|

1050 |

S50C |

1.1213 |

Cf53 |

060A52 |

‐ |

XC48TS |

C53 |

‐ |

1674 |

50 |

|

1055 |

‐ |

1.0535 |

C55 |

070M55 |

9 |

‐ |

C55 |

‐ |

1655 |

55 |

|

1060 |

‐ |

1.0601 |

C60 |

080A62 |

43D |

CC55 |

C60 |

‐ |

‐ |

60 |

|

1055 |

S55C |

1.1203 |

Ck55 |

070M55 |

‐ |

XC55 |

C50 |

C55K |

‐ |

55 |

|

1060 |

S58C |

1.1221 |

Ck60 |

080A62 |

43D |

XC60 |

C60 |

‐ |

1678 |

60Mn |

|

1095 |

‐ |

1.1274 |

Ck101 |

060A96 |

‐ |

XC100 |

‐ |

F.5117 |

1870 |

‐ |

|

W1 |

SK3 |

1.1545 |

C105W1 |

BW1A |

‐ |

Y105 |

C36KU |

F.5118 |

1880 |

‐ |

|

W210 |

SUP4 |

1.1545 |

C105W1 |

BW2 |

‐ |

Y120 |

C120KU |

F.515 |

2900 |

‐ |

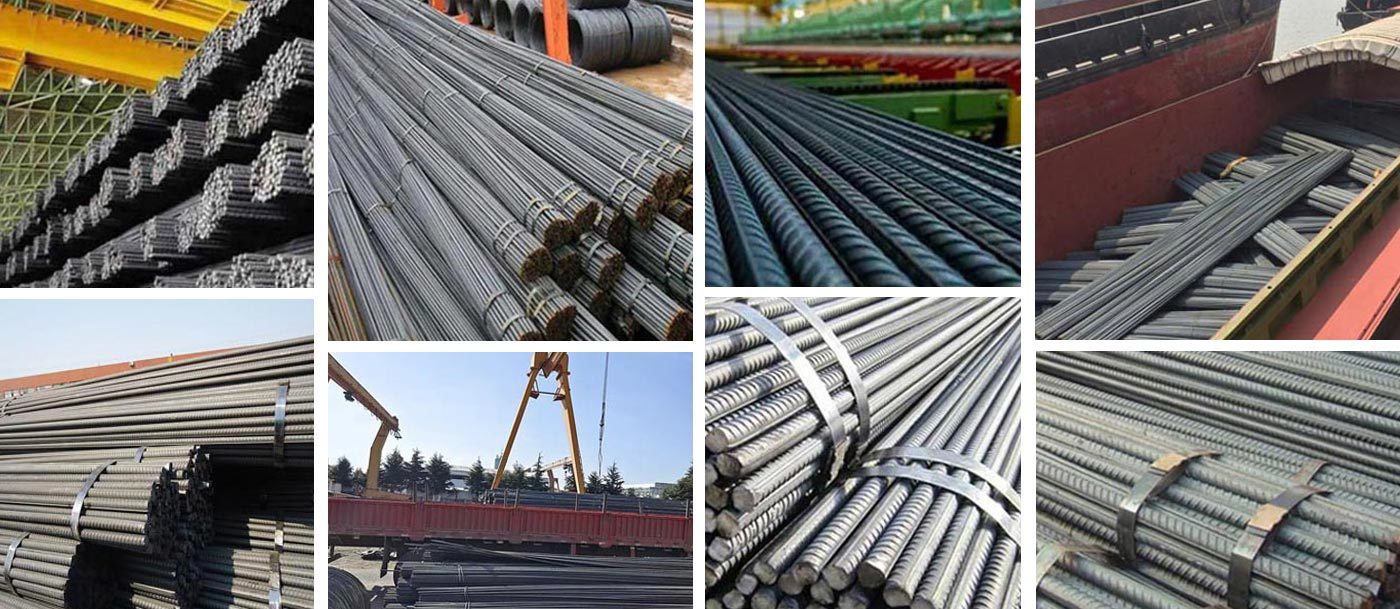

Packing and delivery

With more than ten years of efforts and catering to the growing demands of international markets, the company started to serve global users. As a one-stop supplier of steel and metal raw materials, it currently has become the preferred steel supplier of tens of thousands of customers around the world with its strong supply chains, solid professional knowledge and reliable service. Customers are located in Europe, the Middle East, South America, Southeast Asia and more than 110 countries and regions.

CLIENT FEEDBACK

With more than ten years of efforts and catering to the growing demands of international markets, the company started to serve global users. As a one-stop supplier of steel and metal raw materials, it currently has become the preferred steel supplier of tens of thousands of customers around the world with its strong supply chains, solid professional knowledge and reliable service.

CUSTOMER VISIT

It currently has become the preferred steel supplier of tens of thousands of customers around the world with its strong supply chains, solid professional knowledge and reliable service. Customers are located in Europe, the Middle East, South America, Southeast Asia and more than 110 countries and regions.

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

FACTORY WORKSHOP

APPLICATION AREAS

Oil extraction

Boat

Airplane

Mining Area

Motorcycle

Chemical Industry

Electricity

Oil and gas transportation

FAQ

Wide Application of Galvanized Coil and Its Importance in Modern Industry

Analysis of the characteristics and application fields of bidirectional stainless steel plates

The difference between hot-dip galvanized and electro-galvanized pipes: How to choose according to needs?

Challenges and innovations of duplex stainless steel in marine engineering

Once the products received by customer were found not comply with the products or contract demands, what will you do?

Do you provide samples Is it free or extra?

RELATED PRODUCTS

GET A FREE QUOTE