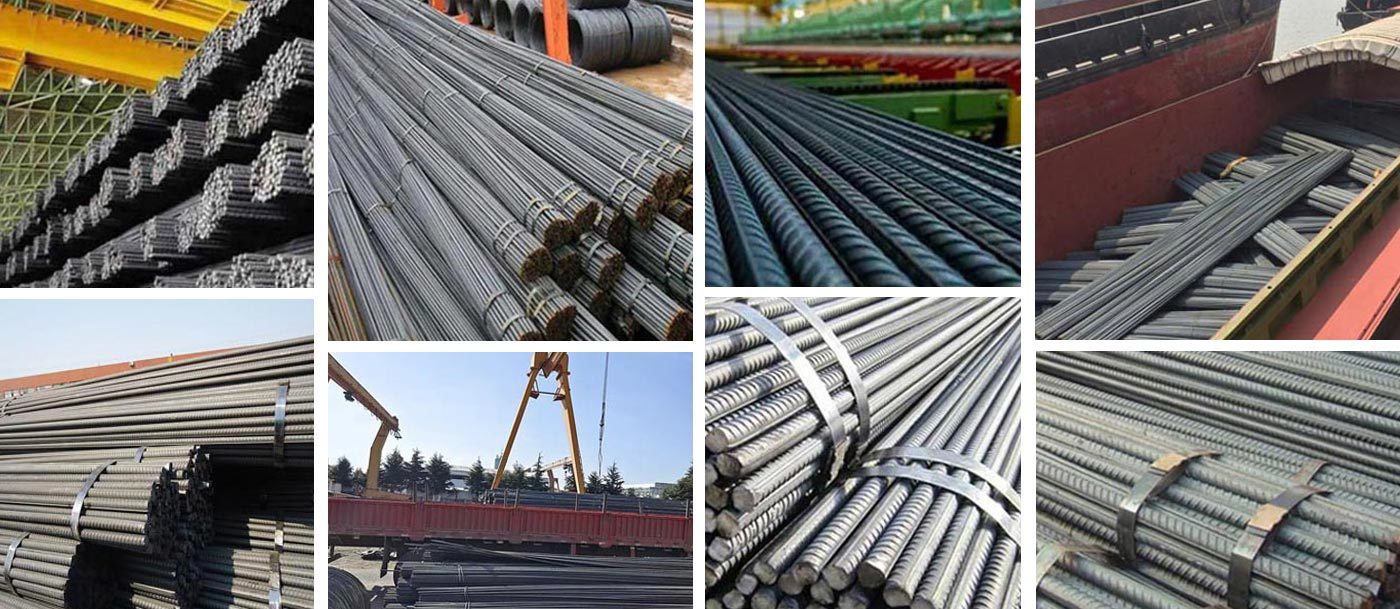

HPB300/HRB335/HRB400/HRB500 Reinforcement

Classification :

PRODUCT DETAILS

HPB300/HRB335/HRB400/HRB500 Reinforcement Description

China's steel bar grade according to the requirements of the Chinese standard GB1499.2-2018. According to the production process, there are hot rolled steel bars (H) and cold rolled steel bars (C). Hot-rolled steel bars are divided into smooth round steel bars (HPB300) and ribbed steel bars. The common brands of hot rolled ribbed steel bars are HRB400, HRBF400, HRB400E, HRBF400E, HRB500, HRBF500, HRB500E and HRB600.

HPB300 (Grade I) is a common steel bar with a diameter of 6-12mm. Commonly used in the production of stirrup, wall reinforcement, etc.

HRB335 (Grade II) is a threaded steel with a diameter of 12-25mm. Commonly used in bridges, dams, houses and other large and medium-sized concrete structures in the beam, column, shear wall. HRB400 (Grade III) is similar to HRB 335, but is stronger and more expensive. Often used in special buildings such as villas.

HRB500 (level 4) diameter 12mm, widely used in large prestressed buildings, such as roofs, crane beams, etc.

Product Parameters

|

Product Name |

HPB300/HRB335/HRB400/HRB500 Reinforcement | |||

|

Standard |

EN/DIN/JIS/ASTM/BS/ASME/AISI, etc. |

|||

|

Common Round Bar Specifications |

3.0-50.8 mm, Over 50.8-300mm |

|||

|

Flat Steel Common Specifications |

6.35x12.7mm, 6.35x25.4mm, 12.7x25.4mm |

|||

|

Hexagon Bar Common Specifications |

AF5.8mm-17mm |

|||

|

Square Bar Common Specifications |

AF2mm-14mm, AF6.35mm, 9.5mm, 12.7mm, 15.98mm, 19.0mm, 25.4mm |

|||

|

Length |

1-6meters, Size Accept Custom |

|||

|

Diameter(mm) |

Hot Rolling Round Bar |

25-600 |

Cold Rolling Square Bar |

6-50.8 |

|

Hot Rolling Square Bar |

21-54 |

Cold Rolling Hexagon Bar |

9.5-65 |

|

|

Cold Rolling Round bar |

6-101.6 |

Forged Rebar |

200-1000 |

|

|

Surface Process |

Bright, Polished, Black |

|||

|

Other Services |

Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. |

|||

Chemical Composition

|

Carbon |

Silicon |

Manganese |

Sulphur |

Phosphorus |

|

0.25% |

0.80% |

1.6% |

0.045% |

0.045% |

Mechanical Properties

|

Chinese Rebar Code |

Yield Strength (Mpa) |

Tensile Strength (Mpa) |

Carbon Content |

|

HRB400, HRBF400, HRB400E, HRBF400E |

400 |

540 |

≤0.25 |

|

HRB500, HRBF500, HRB500E, HRBF500E |

500 |

630 |

≤0.25 |

|

HRB600 |

600 |

730 |

≤ 0.28 |

Scope of Application

Widely used in houses, bridges, roads, especially railways and other civil engineering.

| USA | Japan | Germany | U.K. |

|

France | Italy | Spain | Switzerland | China | |

|

AISI/SAE |

JIS |

W‐nr. |

DIN |

BS |

EN |

AFNOR |

UNI |

UNE |

SS |

GB |

|

A570.36 |

STKM 12A |

1.0038 |

RSt.37‐2 |

4360 |

‐ |

E 24‐2 |

‐ |

‐ |

1311 |

15 |

|

- |

STKM 12C |

- |

- |

40 C |

- |

Ne |

- |

- |

- |

- |

|

1015 |

‐ |

1.0401 |

C15 |

080M15 |

‐ |

CC12 |

C15, C16 |

F.111 |

1350 |

15 |

|

1020 |

‐ |

1.0402 |

C22 |

050A20 |

2C |

CC20 |

C20, C21 |

F.112 |

1450 |

20 |

|

1213 |

SUM22 |

1.0715 |

9SMn28 |

230M07 |

1A |

S250 |

CF9SMn28 |

F.2111 |

1912 |

Y15 |

|

11SMn28 |

||||||||||

|

12L13 |

SUM22L |

1.0718 |

9SMnPb28 |

‐ |

‐ |

S250Pb |

CF9SMnPb28 |

11SMnPb28 |

1914 |

‐ |

|

‐ |

‐ |

1.0722 |

10SPb20 |

‐ |

‐ |

10PbF2 |

CF10Pb20 |

10SPb20 |

‐ |

‐ |

|

1215 |

‐ |

1.0736 |

9SMn36 |

240M07 |

1B |

S300 |

CF9SMn36 |

12SMn35 |

‐ |

Y13 |

|

12L14 |

‐ |

1.0737 |

9SMnPb36 |

‐ |

‐ |

S300PB |

CF9SMnPb36 |

12SMnP35 |

1926 |

‐ |

|

1015 |

S15C |

1.1141 |

Ck15 |

080M15 |

32C |

XC12 |

C16 |

C15K |

1370 |

15 |

|

1025 |

S25C |

1.1158 |

Ck25 |

‐ |

‐ |

‐ |

‐ |

‐ |

‐ |

25 |

|

A572-60 |

‐ |

1.890 |

StE380 |

4360 55 |

‐ |

‐ |

FeE390KG |

‐ |

2145 |

‐ |

|

1035 |

‐ |

1.0501 |

C35 |

060A35 |

‐ |

CC35 |

C35 |

F.113 |

1550 |

35 |

|

1045 |

‐ |

1.0503 |

C45 |

080M46 |

‐ |

CC45 |

C45 |

F.114 |

1650 |

45 |

|

1140 |

‐ |

1.0726 |

35S20 |

212M36 |

8M |

35MF4 |

‐ |

F210G |

1957 |

‐ |

|

1039 |

‐ |

1.1157 |

40Mn4 |

150M36 |

15 |

35M5 |

‐ |

‐ |

‐ |

40Mn |

|

1335 |

SMn438(H) |

1.1167 |

36Mn5 |

‐ |

‐ |

40M5 |

‐ |

36Mn5 |

2120 |

35Mn2 |

|

1330 |

SCMn1 |

1.1170 |

28Mn6 |

150M28 |

14A |

20M5 |

C28Mn |

‐ |

‐ |

30Mn |

|

1035 |

S35C |

1.1183 |

Cf35 |

060A35 |

‐ |

XC38TS |

C36 |

‐ |

1572 |

35Mn |

|

1045 |

S45C |

1.1191 |

Ck45 |

080M46 |

‐ |

XC42 |

C45 |

C45K |

1672 |

Ck45 |

|

1050 |

S50C |

1.1213 |

Cf53 |

060A52 |

‐ |

XC48TS |

C53 |

‐ |

1674 |

50 |

|

1055 |

‐ |

1.0535 |

C55 |

070M55 |

9 |

‐ |

C55 |

‐ |

1655 |

55 |

|

1060 |

‐ |

1.0601 |

C60 |

080A62 |

43D |

CC55 |

C60 |

‐ |

‐ |

60 |

|

1055 |

S55C |

1.1203 |

Ck55 |

070M55 |

‐ |

XC55 |

C50 |

C55K |

‐ |

55 |

|

1060 |

S58C |

1.1221 |

Ck60 |

080A62 |

43D |

XC60 |

C60 |

‐ |

1678 |

60Mn |

|

1095 |

‐ |

1.1274 |

Ck101 |

060A96 |

‐ |

XC100 |

‐ |

F.5117 |

1870 |

‐ |

|

W1 |

SK3 |

1.1545 |

C105W1 |

BW1A |

‐ |

Y105 |

C36KU |

F.5118 |

1880 |

‐ |

|

W210 |

SUP4 |

1.1545 |

C105W1 |

BW2 |

‐ |

Y120 |

C120KU |

F.515 |

2900 |

‐ |

Packing and delivery

With more than ten years of efforts and catering to the growing demands of international markets, the company started to serve global users. As a one-stop supplier of steel and metal raw materials, it currently has become the preferred steel supplier of tens of thousands of customers around the world with its strong supply chains, solid professional knowledge and reliable service. Customers are located in Europe, the Middle East, South America, Southeast Asia and more than 110 countries and regions.

CLIENT FEEDBACK

With more than ten years of efforts and catering to the growing demands of international markets, the company started to serve global users. As a one-stop supplier of steel and metal raw materials, it currently has become the preferred steel supplier of tens of thousands of customers around the world with its strong supply chains, solid professional knowledge and reliable service.

CUSTOMER VISIT

It currently has become the preferred steel supplier of tens of thousands of customers around the world with its strong supply chains, solid professional knowledge and reliable service. Customers are located in Europe, the Middle East, South America, Southeast Asia and more than 110 countries and regions.

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

FACTORY WORKSHOP

APPLICATION AREAS

Oil extraction

Boat

Airplane

Mining Area

Motorcycle

Chemical Industry

Electricity

Oil and gas transportation

FAQ

Wide Application of Galvanized Coil and Its Importance in Modern Industry

Analysis of the characteristics and application fields of bidirectional stainless steel plates

The difference between hot-dip galvanized and electro-galvanized pipes: How to choose according to needs?

Challenges and innovations of duplex stainless steel in marine engineering

Once the products received by customer were found not comply with the products or contract demands, what will you do?

Do you provide samples Is it free or extra?

RELATED PRODUCTS

GET A FREE QUOTE